The new era of manufacturing is here. Unfortunately, this might not be the best news for workers in the United States, the United Kingdom, and around the globe. A leading professor emeritus of artificial intelligence and robotics in the U.K. predicts a massive surge of unemployment as robotics become commonplace. Although he made this comment recently, others have voiced similar concerns in recent years.

Three years ago, scholars at Oxford stated that 47 percent of the American workforce could soon find themselves without jobs. Their report indicated that professions requiring a high degree of education and people contact, such as doctors and lawyers, were safe from automation. However, current trends tell a different story. Jobs that no one could imagine being performed by robots even five years ago are now are increasingly falling into that category.

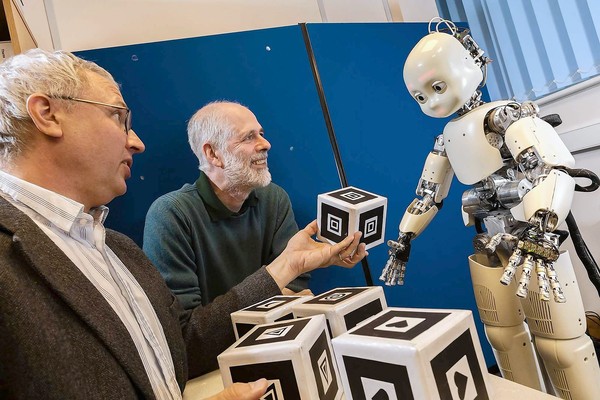

Robots Fill Roles from Entry-Level to Highly Skilled

It is nothing new to get food quickly in a restaurant. After all, fast food restaurants have been around for decades. Ordering from a kiosk and getting a meal 90 seconds later with no human contact is something else entirely. The robotics behind this development eliminates the need for cashiers, waiters and waitresses, and even cooks.

Robots can even take over the job of a human legal researcher. In the summer of 2015, a newly developed legal assistant tool joined forced with IBM’s super-computer for the first time. The result was a robot that could perform research in seconds instead of hours. While bad news for law firm researchers, it is a promising development for people who can’t currently afford legal representation. The robot cut costs by as much as 80 percent.

Adios to Shoes Made by Hand

The Adidas Shoe Company in Germany recently announced 500 prototypes for robots to start making its signature product. This is a big change from its earlier practice of outsourcing the work to manufacturing plants in China and other Asian countries.

If the experiment proves worthwhile, it will end the practice of sending work to low-paying markets and instead cause the company to build robotics facilities. This could have huge implications for companies in the United States that copy the idea of keeping robotic manufacturing plants in local communities rather than sending work overseas.

The Dawn of a New Industrial Revolution

Robotics, artificial intelligence, and workforce automation are nothing new. What is new is how they are changing engineering and manufacturing to disciplines with greater creativity, localization, and personalization.

Engineers, for example, will be able to improve their efficiency by having much of the problem-solving done for them at the beginning of a project. With a computer to generate cheaper and better options, engineers can solve complex problems much sooner. This not only benefits them, but the people who rely on their products and services.

More adaptation will be required of those who work in manufacturing and construction. These workers will be left behind if they don’t learn more sophisticated skills or move to faster-growing industries such as education and healthcare. Manufacturing in the United States will likely never be as big as it once was. However, changes, such as local and personal manufacturing, mean lower prices for consumers and ultimately keep jobs here at home.

Article Submitted By Community Writer